In the process of beer brewing, wort preparation is a complex physical and chemical change process. Because beer brewing is successful or not, wort preparation is a very critical process, so brewmasters are careful, but often some details are often overlooked during brewing, so we share with you the knowledge of changes in wort in post-processing In order to facilitate everyone to prepare the perfect wort.

NO.1 wort oxygen absorption

At high temperatures, the polyphenols in the wort can easily react with oxygen, resulting in an increase in the color of the semi-finished wort and future beer; moreover, due to the oxidation reaction, the reducing substances in the wort will decrease and the antioxidant capacity Significantly reduced, therefore, in the whole process of wort preparation, contact with oxygen (including the original material) should be avoided as much as possible. Because of this, hot wort should not be ventilated and contacted with oxygen before cooling.

At low temperatures (below 40 ° C), oxygen is mainly dissolved in wort by physical action, and its dissolved amount is inversely proportional to the temperature and concentration of wort. For example, at 85 ℃, the dissolved oxygen content is only 1/5 ~ 1/10 of that at 45 ℃; at 5 ℃, the saturated dissolved oxygen content of 14 ° P wort is 4.55mL / L, and 7 ° The dissolved oxygen content of P wort was 5.6mL / L.

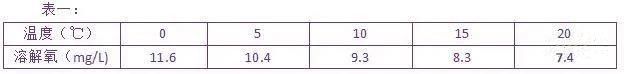

The dissolved oxygen content of wort with the same concentration is related to wort temperature, wort movement status, air pressure and other factors. Under 0.1MPa pressure, the saturated dissolved oxygen content of 12 ° P wort at different temperatures is shown in Table 1 below

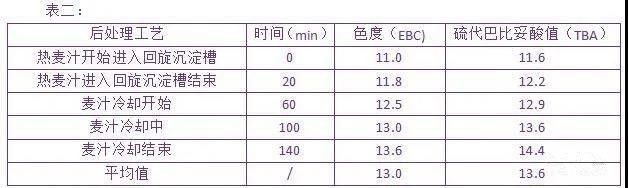

The total time from the entry of hot wort into the gyratory sedimentation tank to the end of wort cooling should not exceed 110 min or less at a high temperature of 90 ° C to 95 ° C. During this period of time, the increased color of wort is relatively good within the allowable range of 1.0 ~ 1.5EBC. If the time is too long, the wort will increase oxygen absorption, and the color will be obviously deepened, which not only affects the color and taste of beer And the stability of the finished beer will be worse. The color change of wort during post-treatment is shown in Table 2 below

NO.2 Increased bitterness

The bitter substances in wort are mainly reflected by the isomerization of α-acid. After boiling, the wort should be allowed to stand for 20 to 40 minutes in the convoluted sedimentation tank. At this time, the remaining α-acid in the hops can still be leached by the hot wort, and the content of isohumulone can be increased by 15% to 25%.

NO.3 Water evaporation

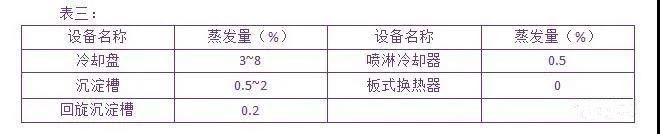

During whirling and cooling of wort, part of the water will evaporate, and the amount of evaporation is related to equipment conditions, wort concentration, ventilation and external climatic conditions. Due to the evaporation of water, the wort concentration has increased accordingly. See Table 3 for the evaporation of water using different cooling equipment.

In order to make the wort reach the concentration specified in the process after cooling, the equipment should be measured for water evaporation in advance, and it must be considered that after cooling, the use of quantitative hot water in the top plate heat exchanger and the wort in the pipe will cause the concentration Reduce the problem to avoid the phenomenon that the concentration of stereotyped wort is high and low, which affects the stability of product quality or causes undesirable waste.